Get Ahead. Stay Ahead.

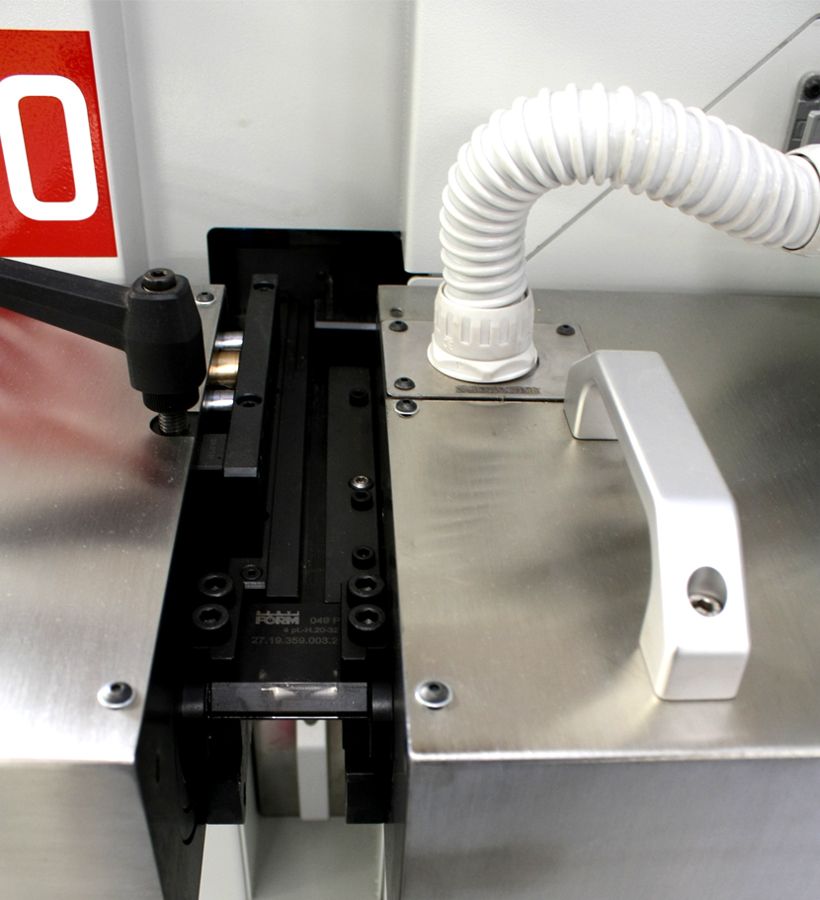

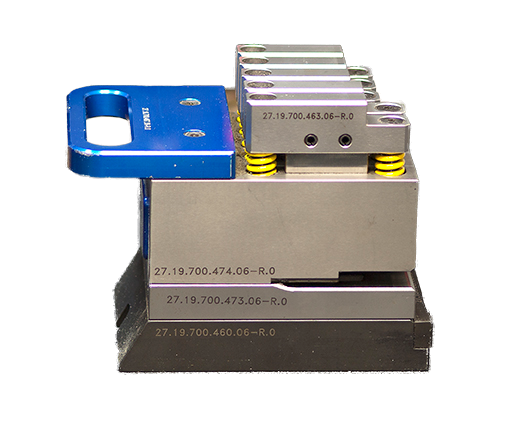

Slow production, unreliable foreign machines, and constant maintenance are holding your shop back. Without the right tools, staying competitive feels impossible. The Eco 2.0 changes that—fully electric, built for speed, and packed with customization options. It’s the bender that works as hard as you do.