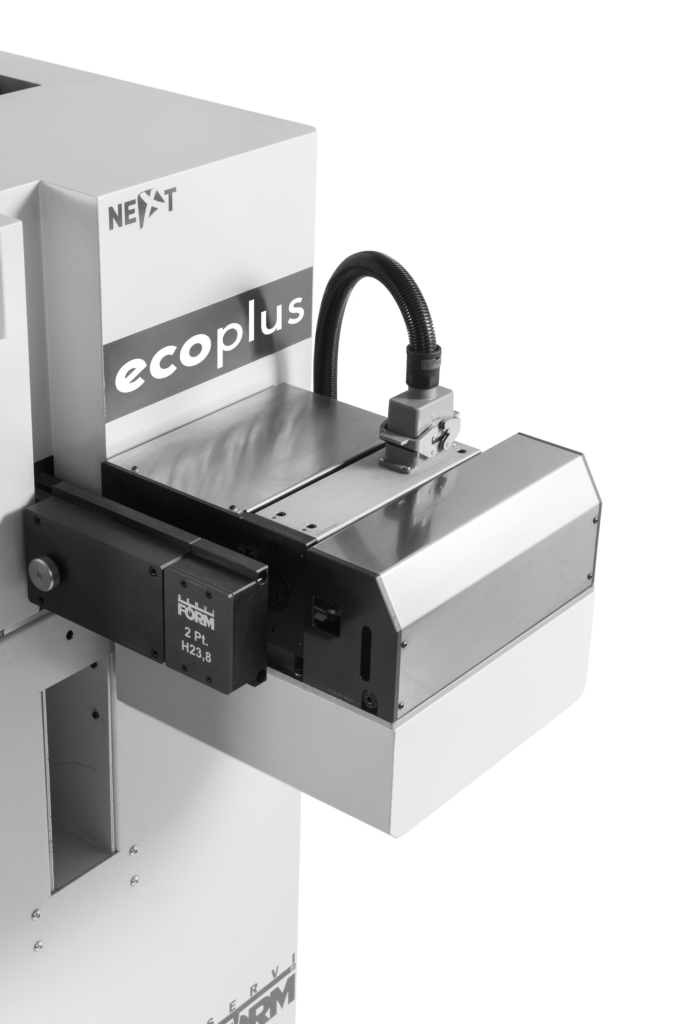

The Heavy Hitter Your Die Shop’s Been Waiting For.

Standard benders weren’t built for the heavy-duty work—thicker materials like corrugated board and plastic slow them down, costing you time, money, and opportunities. Switching rule sizes? That’s a whole operation in itself, dragging production to a halt. For die makers looking to grow into new industries or tackle a wider range of jobs, those old limitations are holding you back.

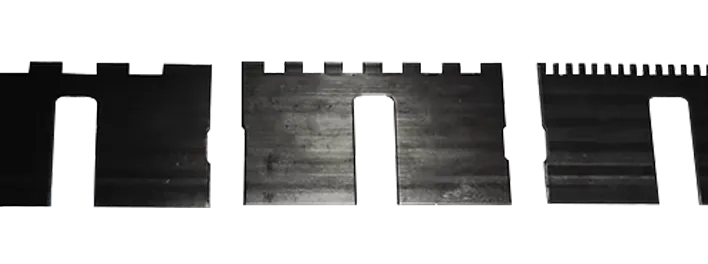

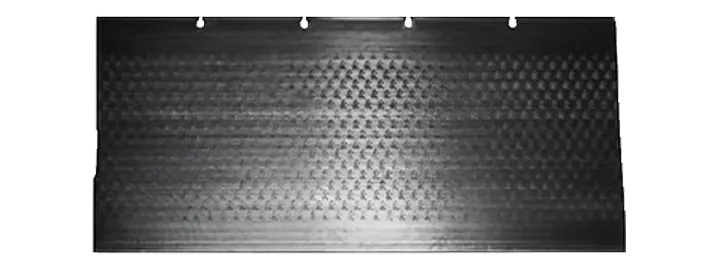

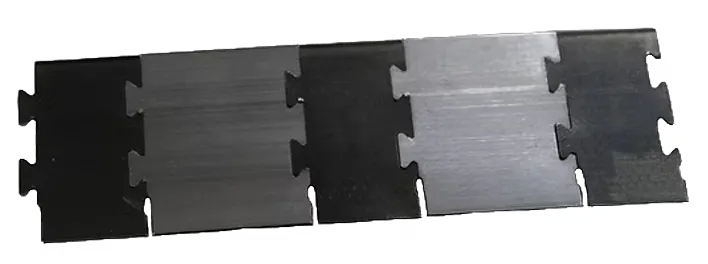

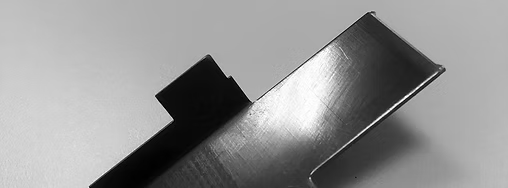

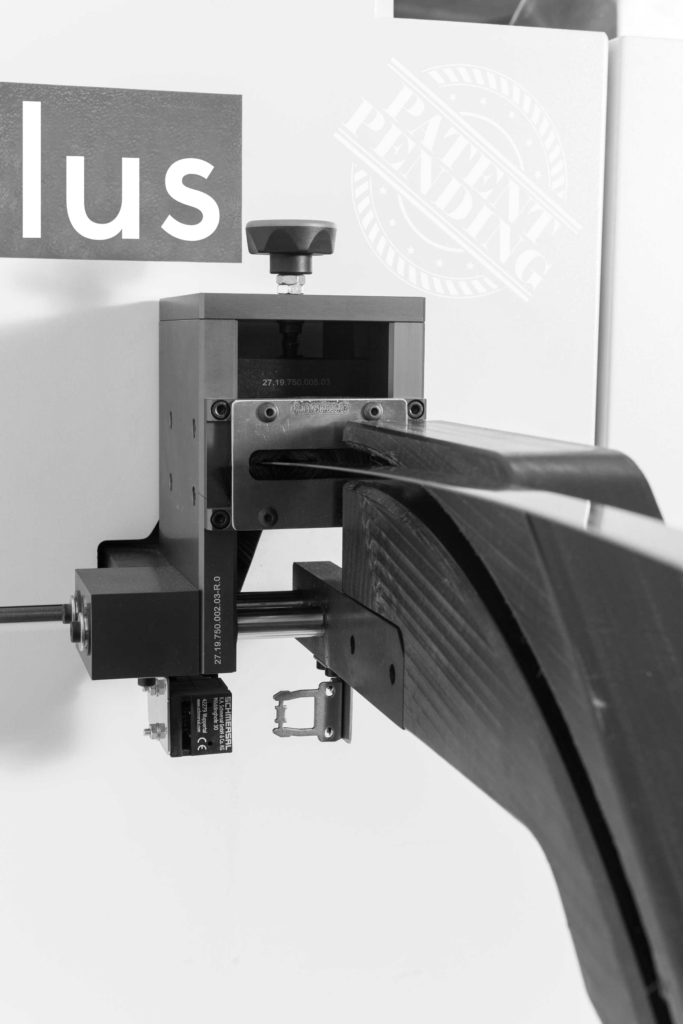

Enter the EcoGiant—built to bend 3-4 point rule with zero hesitation, no matter the material. Its bend-first, cut-last technology ramps up speed without sacrificing precision, while fast rule changeovers keep your shop moving. Whether it’s joint lock for thermoformers or dynamic stripping claws, the EcoGiant’s advanced cartridge system handles it all. It's the most versatile auto bender out there, engineered for die makers who demand more—more power, more flexibility, more control.

Enter the EcoGiant—built to bend 3-4 point rule with zero hesitation, no matter the material. Its bend-first, cut-last technology ramps up speed without sacrificing precision, while fast rule changeovers keep your shop moving. Whether it’s joint lock for thermoformers or dynamic stripping claws, the EcoGiant’s advanced cartridge system handles it all. It's the most versatile auto bender out there, engineered for die makers who demand more—more power, more flexibility, more control.