Meet the Game-Changer Your Die Shop’s Been Missing.

Multiple machines, manual steps, and scattered punching slow down production and raise labor costs. Sorting finished pieces takes time, and specialized cuts demand hands-on adjustments that increase the chance of errors.

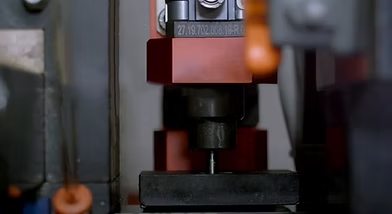

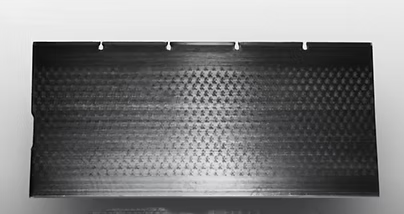

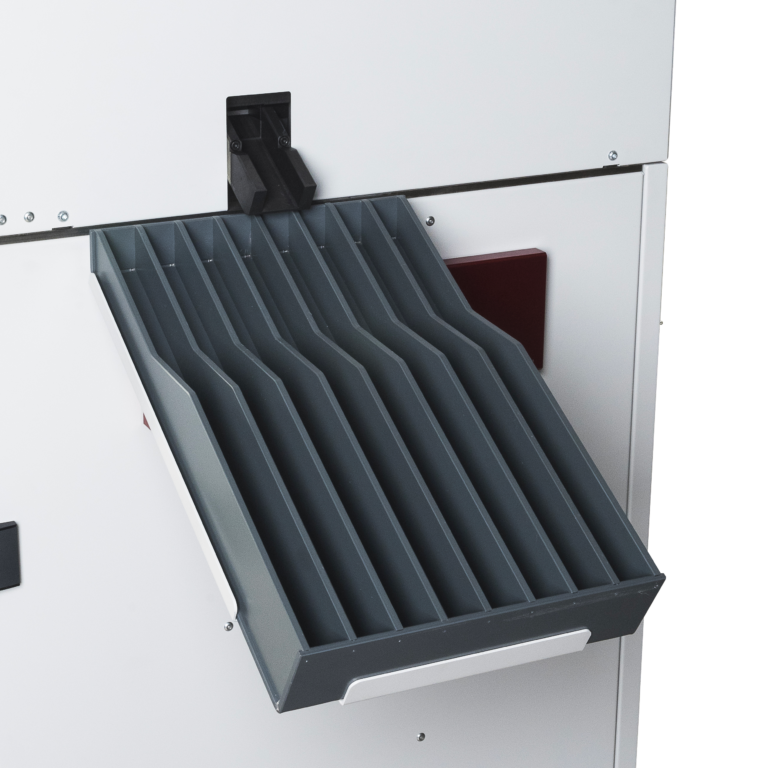

IntegraCrease streamlines it all. One system handles creasing and straight rule production with centralized punching, remote programming, and automatic sorting. Built-in options like bottom cut, lasercrease, and dimpling eliminate the need for manual tweaks. It’s the seamless solution for die shops ready to level up automation and efficiency.

IntegraCrease streamlines it all. One system handles creasing and straight rule production with centralized punching, remote programming, and automatic sorting. Built-in options like bottom cut, lasercrease, and dimpling eliminate the need for manual tweaks. It’s the seamless solution for die shops ready to level up automation and efficiency.