Stripping Tools, Your Way—Every Time

Stripping tool production has long been a bottleneck—manual steps, costly third-party components, and limited machine capabilities all slow down your workflow. For diemakers working with corrugated material, that means higher costs, longer lead times, and less flexibility in-house. The inefficiencies add up fast.

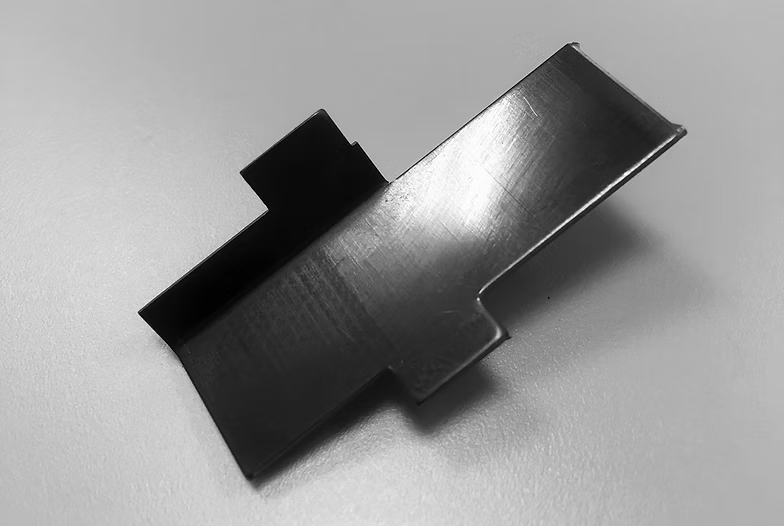

The IntegrAStrip changes everything. This fully automated system handles both beveled and flat top steel rule with precision, reading directly from your CAD files. Its integrated bending head and dynamic stripping claws give you the power to create custom tools in-house—no outsourcing, no delays. Fully electric and built for streamlined performance, IntegrAStrip reduces labor, eliminates waste, and puts you in full control of your stripping tool production.

The IntegrAStrip changes everything. This fully automated system handles both beveled and flat top steel rule with precision, reading directly from your CAD files. Its integrated bending head and dynamic stripping claws give you the power to create custom tools in-house—no outsourcing, no delays. Fully electric and built for streamlined performance, IntegrAStrip reduces labor, eliminates waste, and puts you in full control of your stripping tool production.