Bend faster. Stay consistent. Upgrade without looking back.

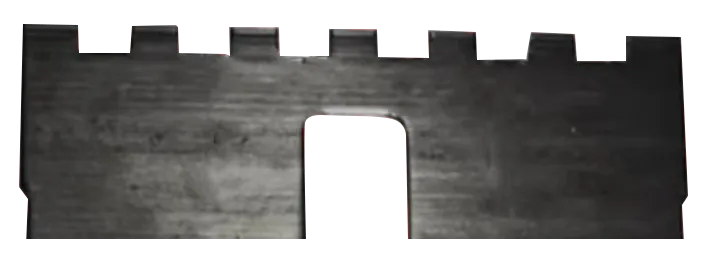

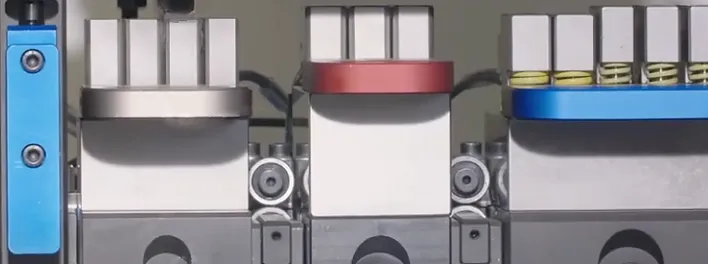

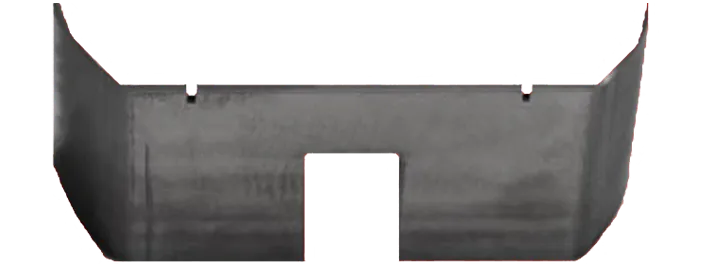

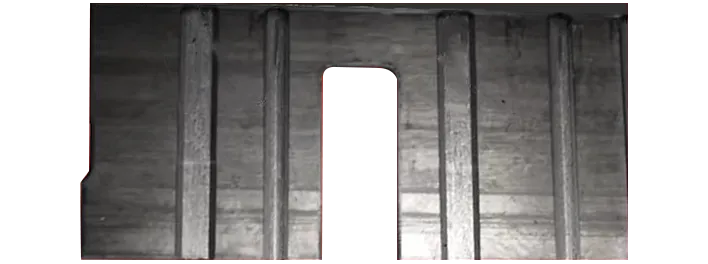

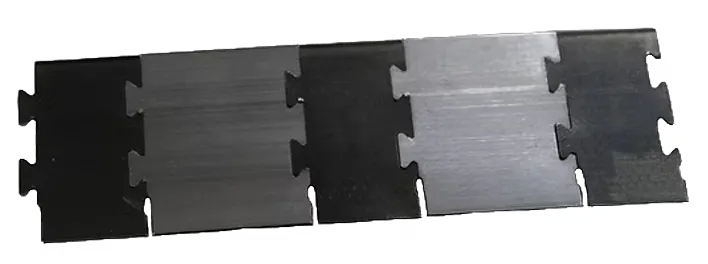

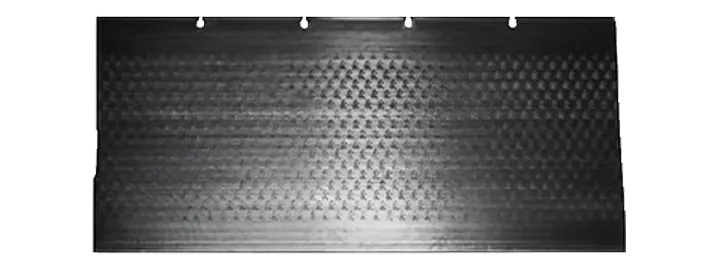

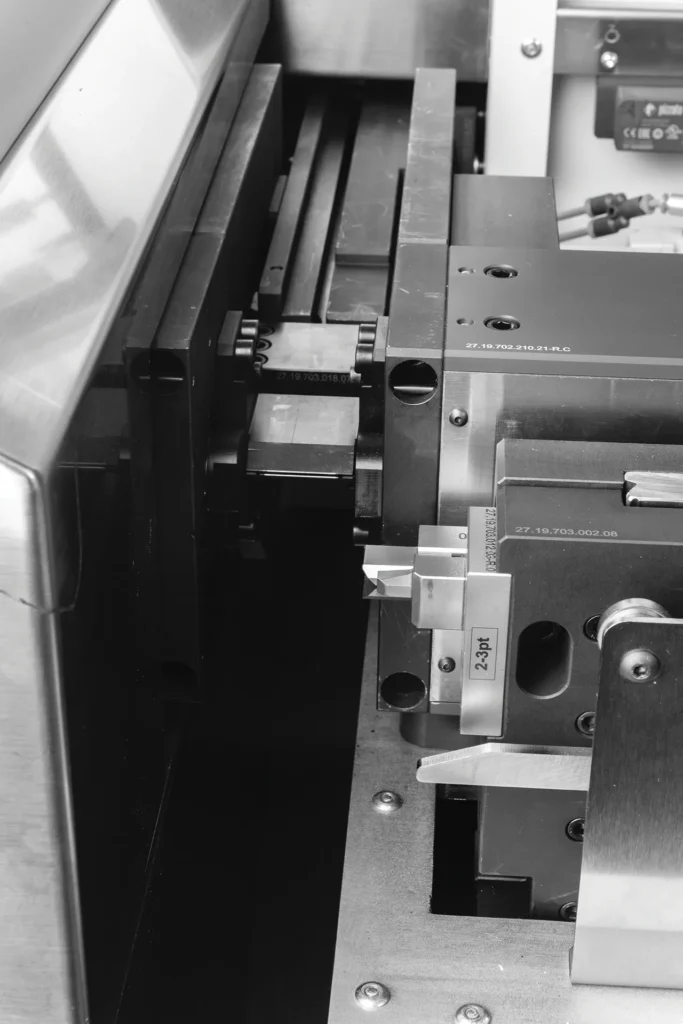

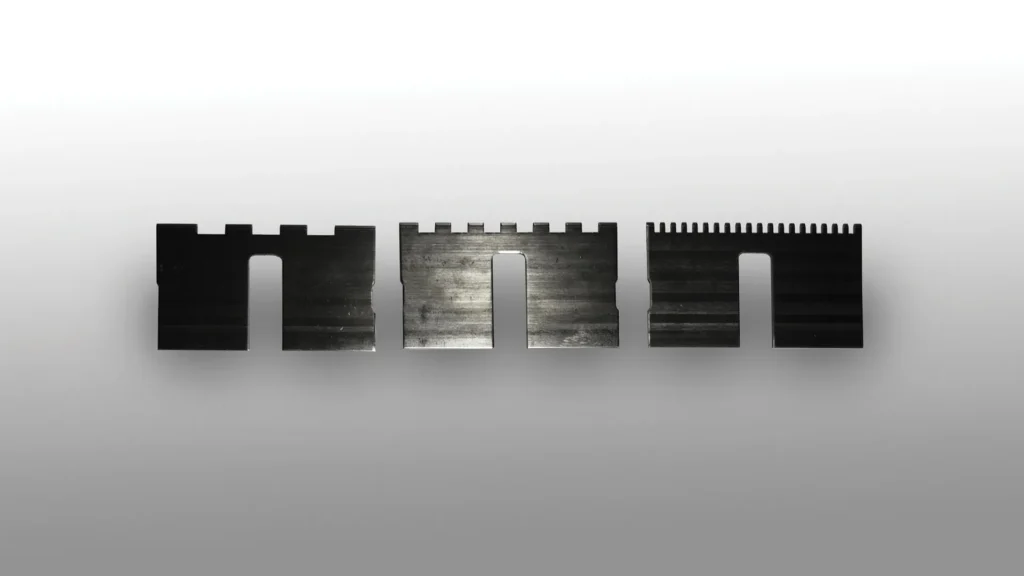

Production delays, bad bends, and inconsistent nicks cost time and money—and your customers won’t wait. Every missed deadline chips away at your efficiency and credibility. For high-end die shops, speed and consistency aren’t just nice to have—they're survival. That’s where the LineA steps in. Engineered for performance, it delivers 33% faster bending, flawless nicks with a 6-wheel grinding unit, and multi-function versatility—all in one powerful machine. With the LineA, you stay on schedule, cut waste, and keep your operation running smooth and strong.