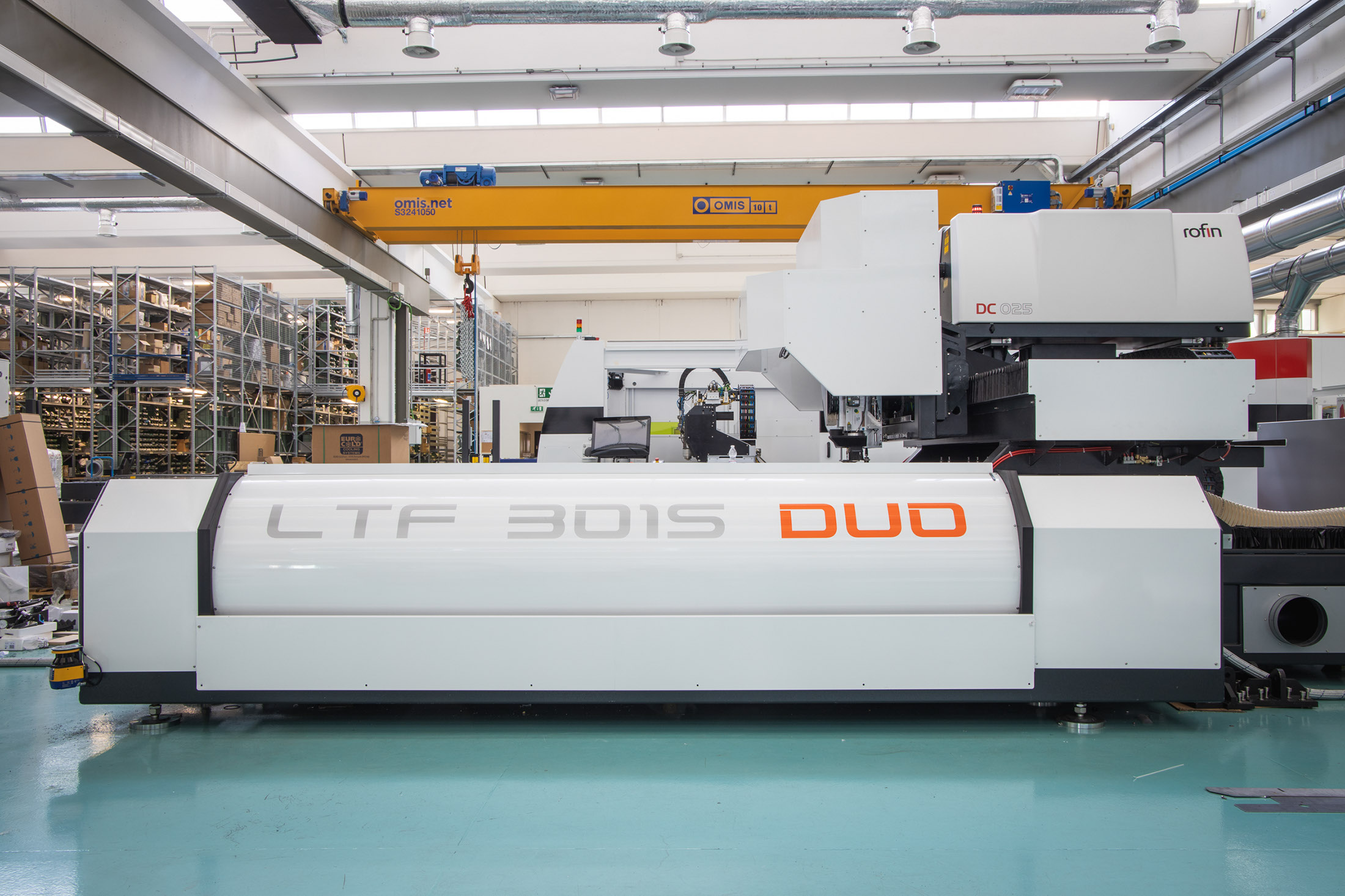

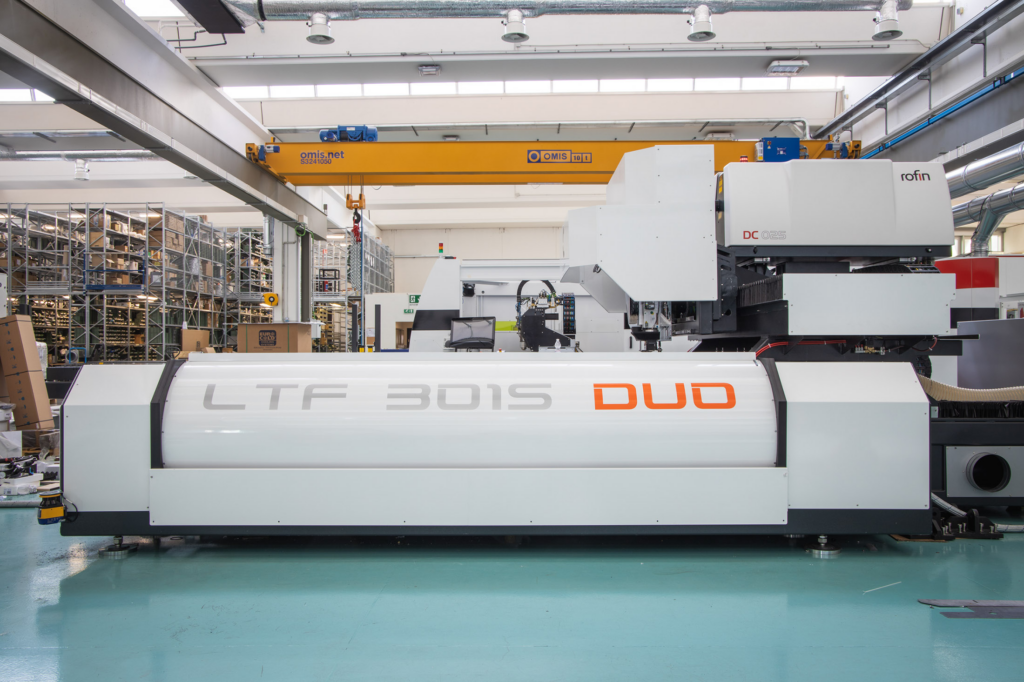

One Machine. Every Job. No Compromise.

Running both flatbed and rotary jobs shouldn’t mean running out of space—or patience. Slower systems, constant changeovers, and limited automation eat into your time and profit. For die shops tackling a variety of high-volume jobs, juggling multiple machines only adds complexity and slows you down.

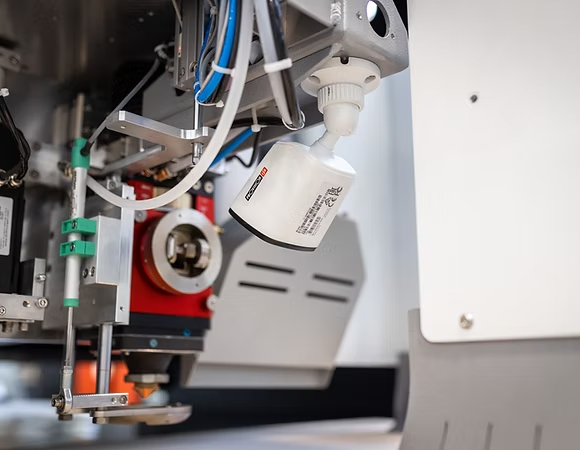

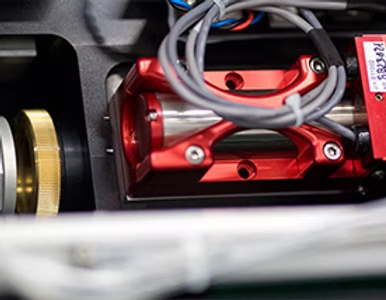

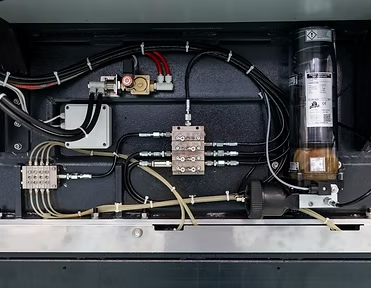

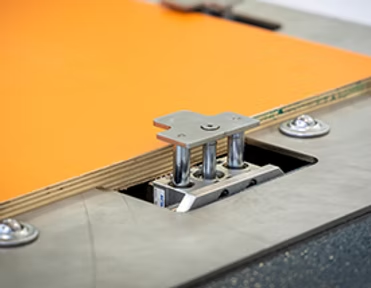

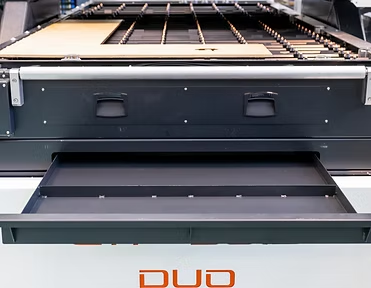

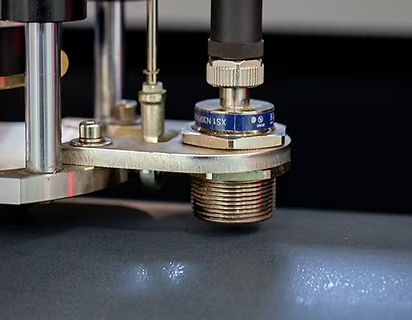

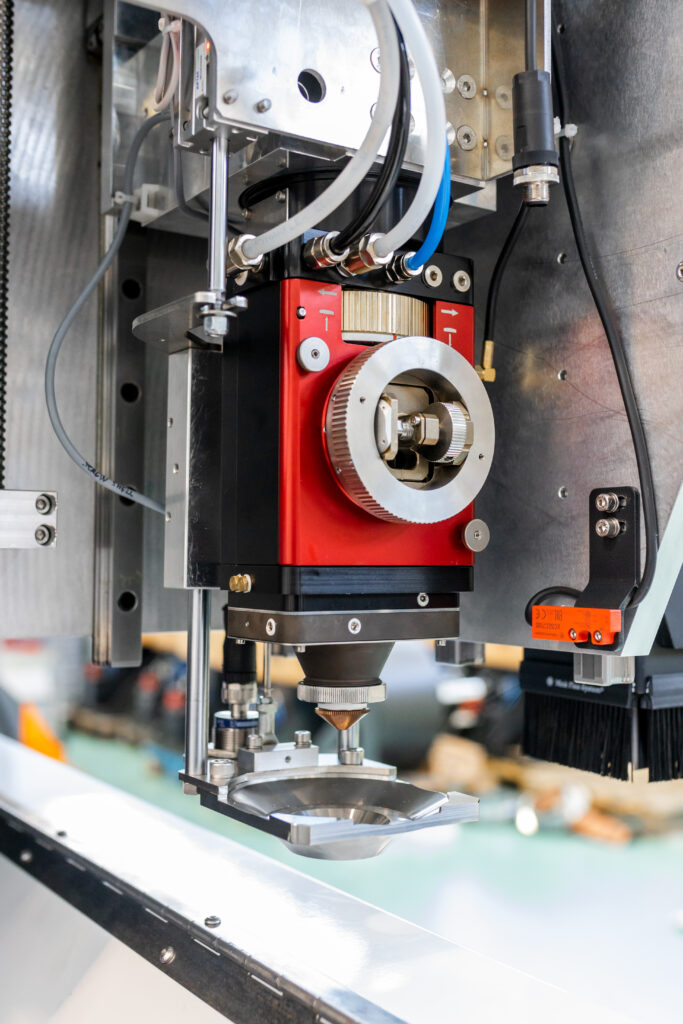

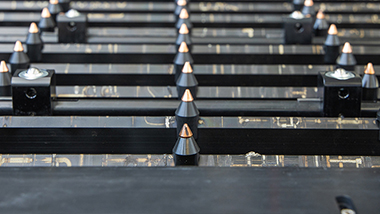

The LTF DUO changes the game. It combines rotary and flatbed laser cutting into one powerful, space-saving system built for nonstop performance. With advanced software, magnetic crash protection, and direct CAD file import, it’s ready to handle anything from folding cartons to corrugated boards—fast and with pinpoint accuracy. When you need flexibility, speed, and smart automation all in one rugged package, the LTF DUO gets the job done right.

The LTF DUO changes the game. It combines rotary and flatbed laser cutting into one powerful, space-saving system built for nonstop performance. With advanced software, magnetic crash protection, and direct CAD file import, it’s ready to handle anything from folding cartons to corrugated boards—fast and with pinpoint accuracy. When you need flexibility, speed, and smart automation all in one rugged package, the LTF DUO gets the job done right.