Built for High Volume. Ready for Anything.

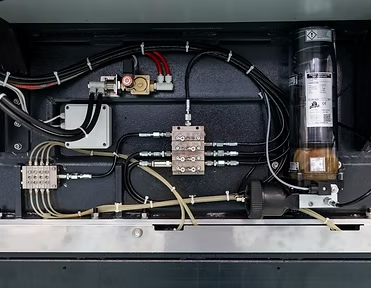

When demand is high and downtime isn’t an option, die shops need more than just a laser—they need a workhorse. The LTFP delivers unmatched speed, precision, and reliability, designed to power through up to three shifts a day without missing a beat. Traditional methods can’t compete when you’re looking to grow, scale, and stay ahead of the curve.

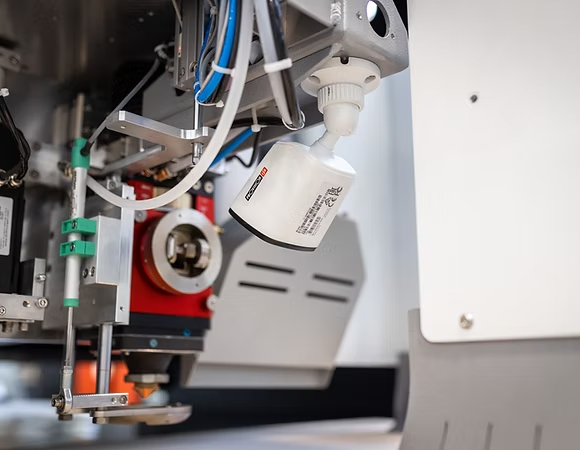

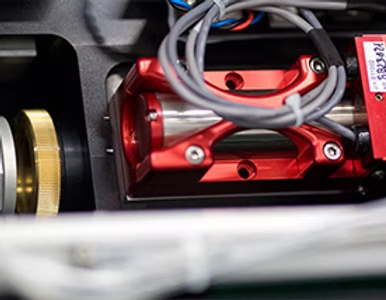

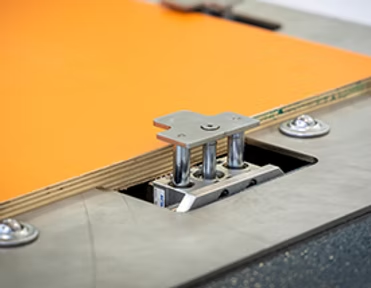

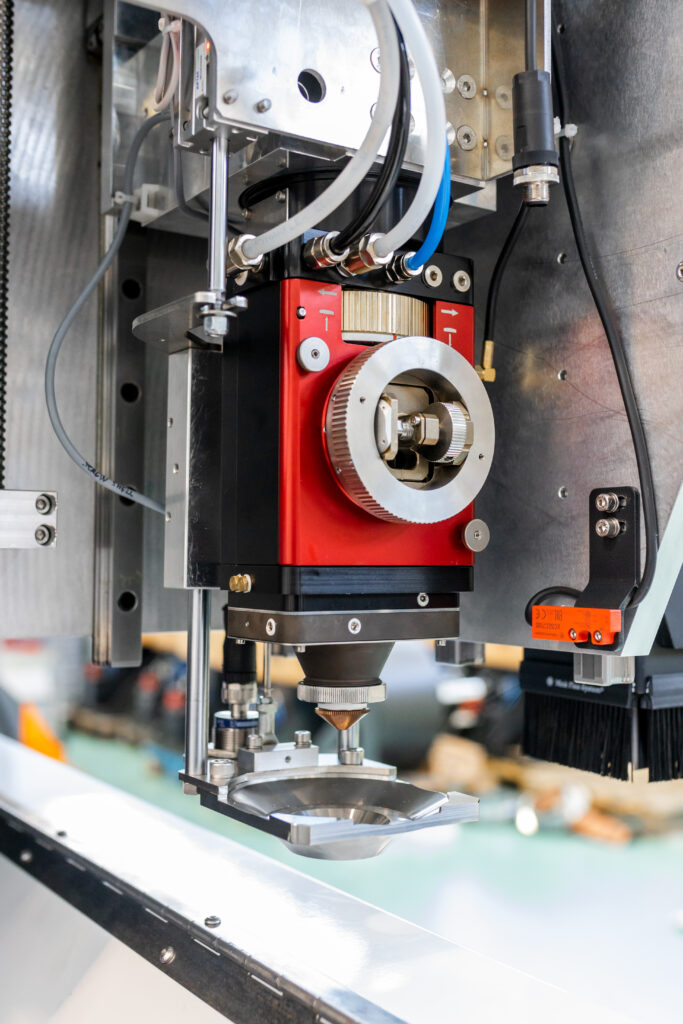

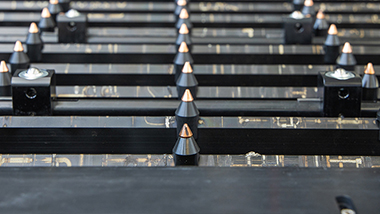

With advanced X, Y, and Z axis movement, a compact footprint, and automation that simplifies production, the LTFP is everything a high-output die shop needs. It comes packed with over ten customizable options—no extra cost, no compromise. Built tough for diemakers who refuse to slow down, the LTFP sets a new standard in flatbed laser performance.

With advanced X, Y, and Z axis movement, a compact footprint, and automation that simplifies production, the LTFP is everything a high-output die shop needs. It comes packed with over ten customizable options—no extra cost, no compromise. Built tough for diemakers who refuse to slow down, the LTFP sets a new standard in flatbed laser performance.