Precision That Powers Productivity.

When you're cutting complex layouts and handling heavy-duty materials, standard lasers just don’t cut it. Multiple setups, clunky loading, and outdated tech slow you down and drive up costs. For diemakers producing folding carton and corrugated board at scale, speed and accuracy aren’t optional—they’re mission-critical.

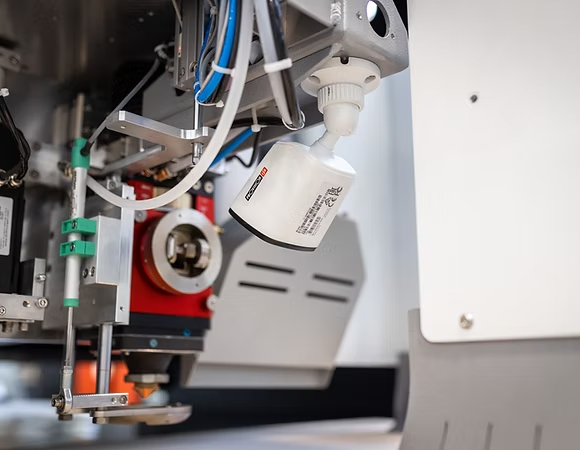

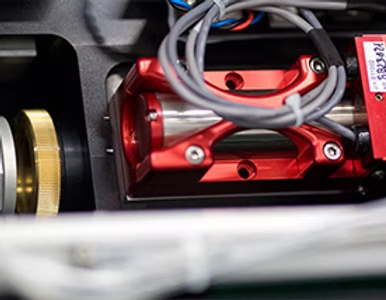

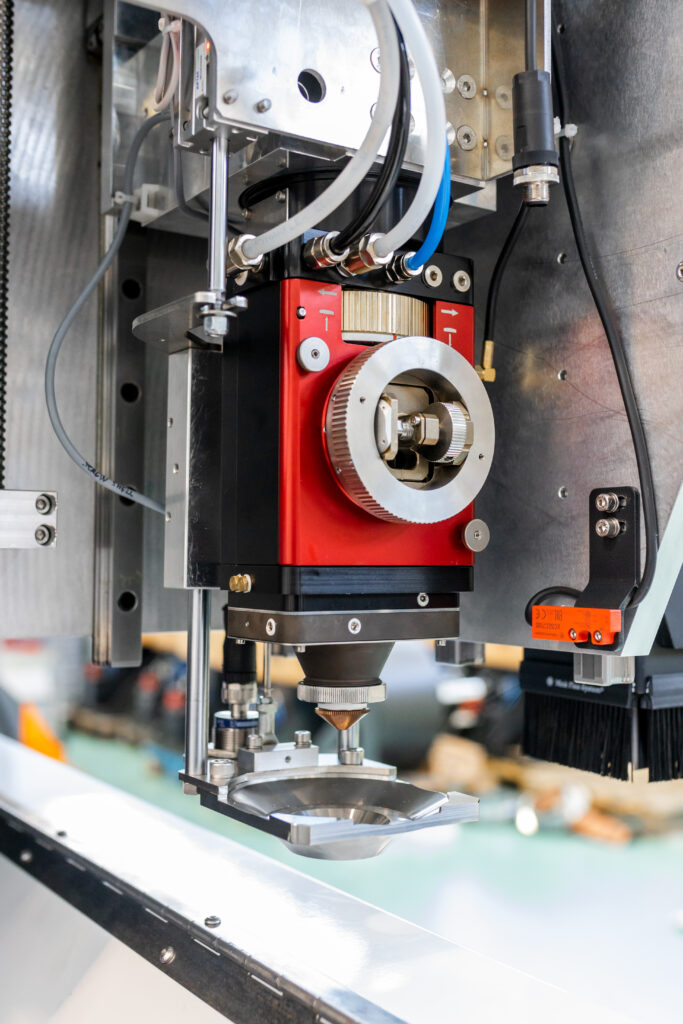

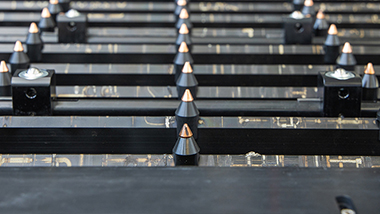

The OF Flatbed Laser is built to handle it all. Cross-table technology delivers pinpoint precision, while a smart side-mounted laser source simplifies loading of large die boards and steel sheets. Fully customizable and engineered for decades of reliable output, the OF combines rock-solid durability with next-level flexibility. It’s the powerhouse laser system that keeps up with your toughest jobs—shift after shift.

The OF Flatbed Laser is built to handle it all. Cross-table technology delivers pinpoint precision, while a smart side-mounted laser source simplifies loading of large die boards and steel sheets. Fully customizable and engineered for decades of reliable output, the OF combines rock-solid durability with next-level flexibility. It’s the powerhouse laser system that keeps up with your toughest jobs—shift after shift.