Built for Speed, Engineered for Precision

Rotary die shops running on outdated tech are forced to choose between speed, accuracy, and profitability. Slower systems, manual setups, and inconsistent cuts lead to wasted material, rework, and rising labor costs. When you’re trying to stay competitive and scale production, those compromises add up fast.

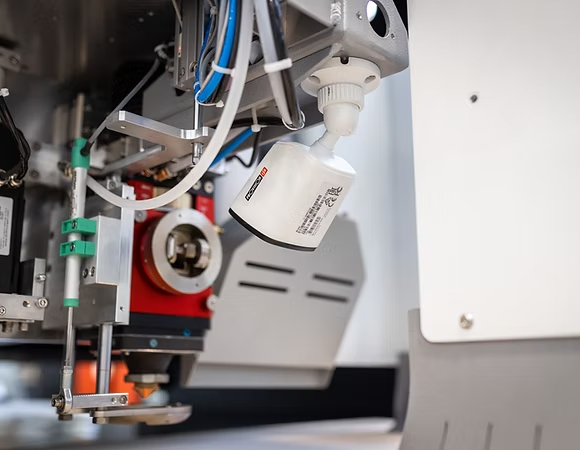

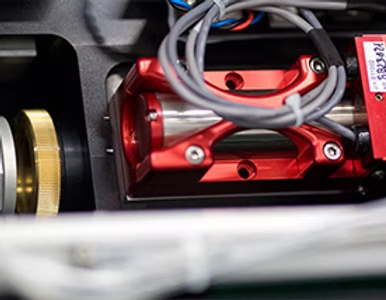

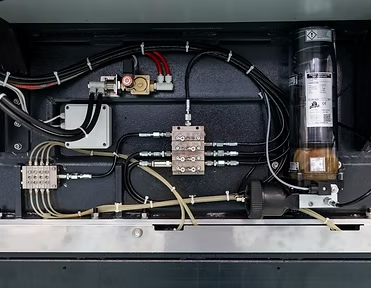

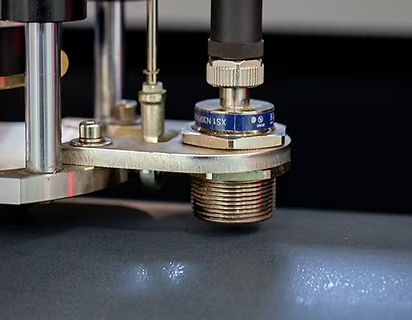

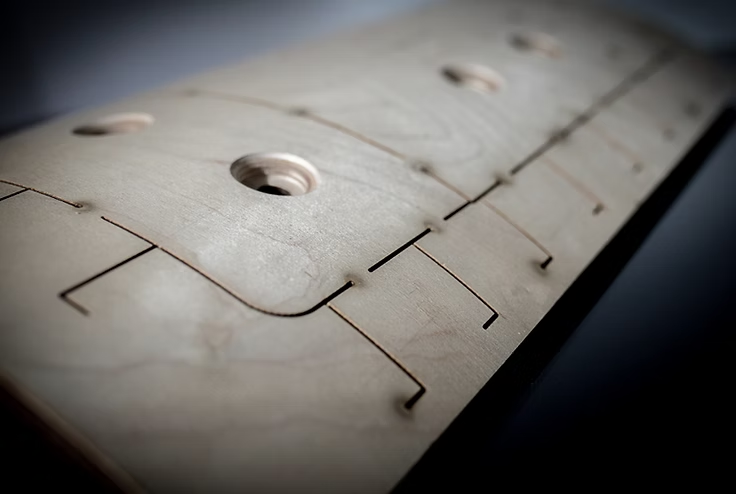

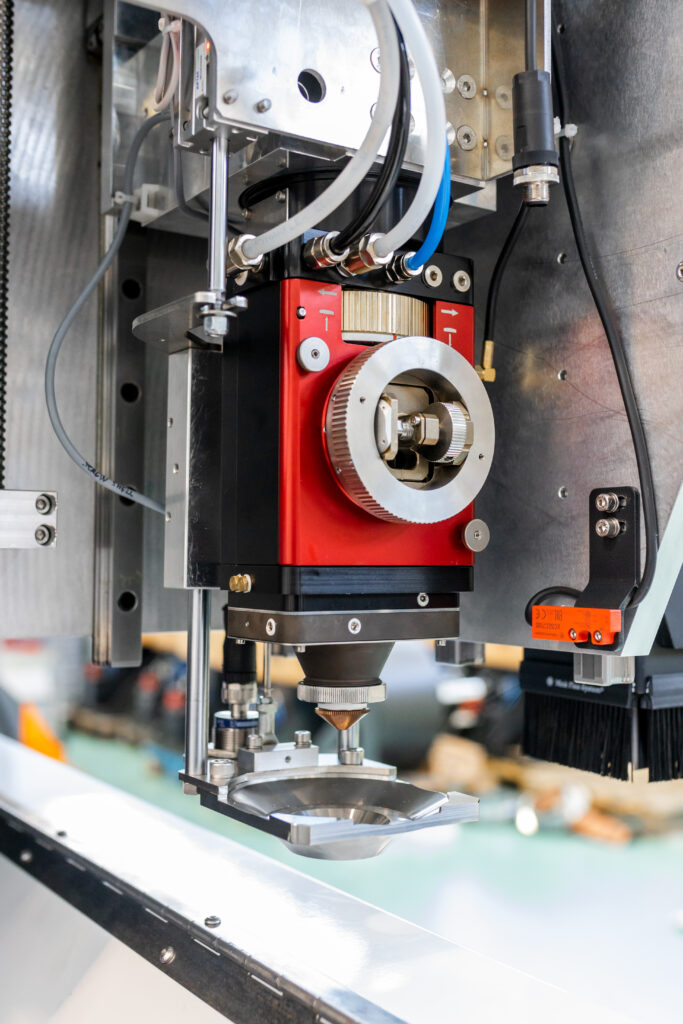

The OFR Rotary Laser changes that. Purpose-built for high-volume rotary die making, it delivers pinpoint accuracy, fast production, and reliable automation—all in one rugged system. With cross-table technology for long-term precision and smart digital controls that streamline your workflow, the OFR helps you cut sharper, faster, and smarter. For shops ready to level up and lead the pack, this is the rotary laser built to deliver.

The OFR Rotary Laser changes that. Purpose-built for high-volume rotary die making, it delivers pinpoint accuracy, fast production, and reliable automation—all in one rugged system. With cross-table technology for long-term precision and smart digital controls that streamline your workflow, the OFR helps you cut sharper, faster, and smarter. For shops ready to level up and lead the pack, this is the rotary laser built to deliver.