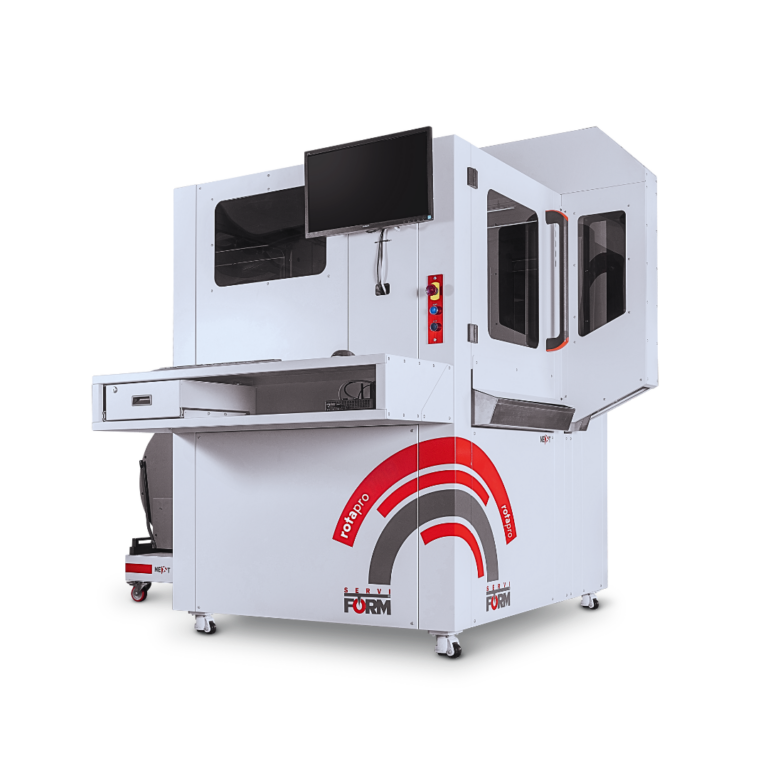

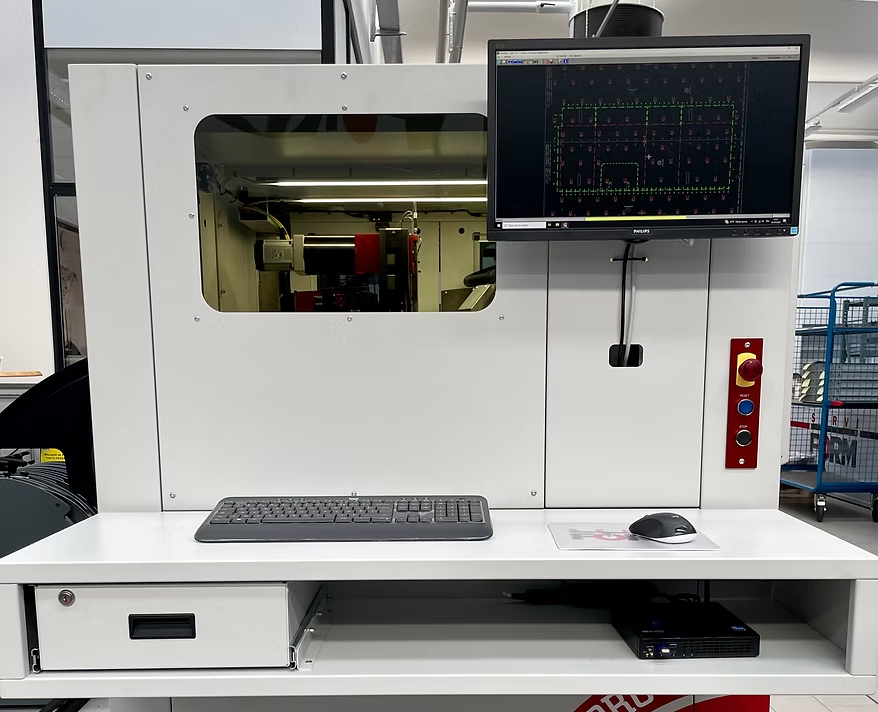

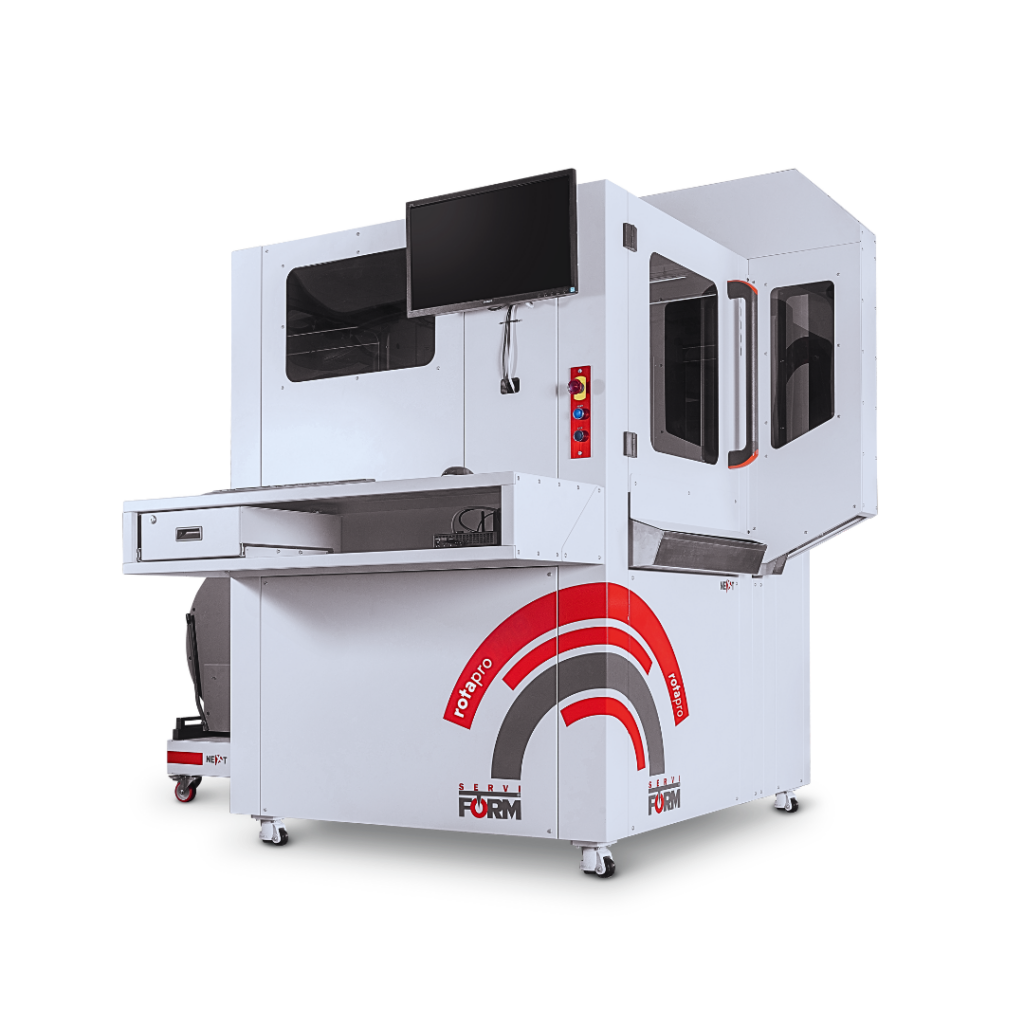

Unleash the Full Power of Rotary Bending.

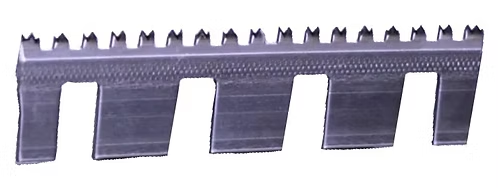

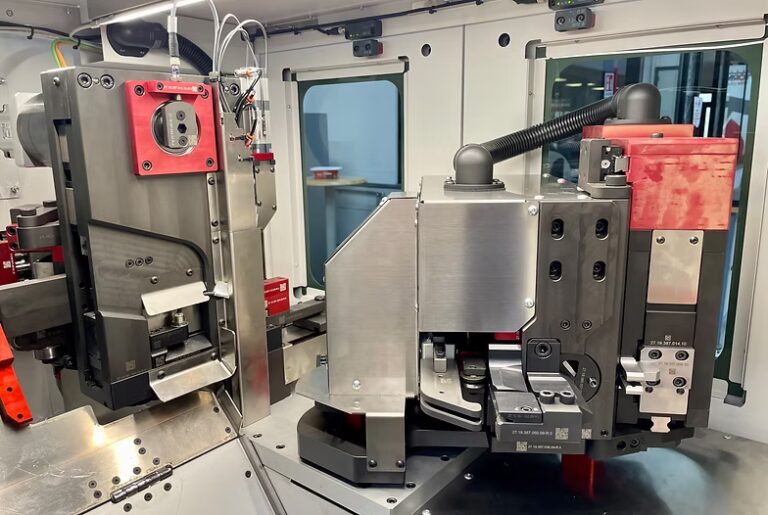

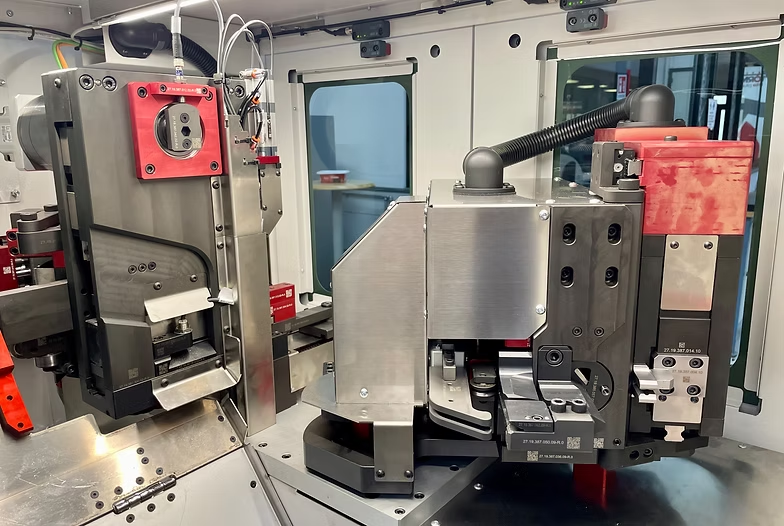

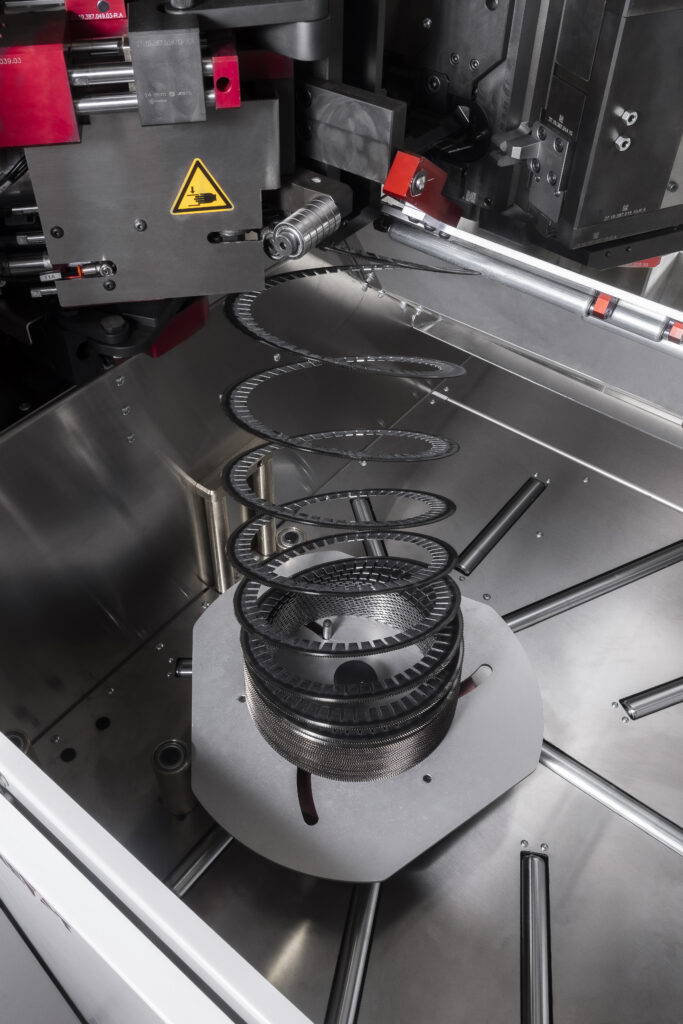

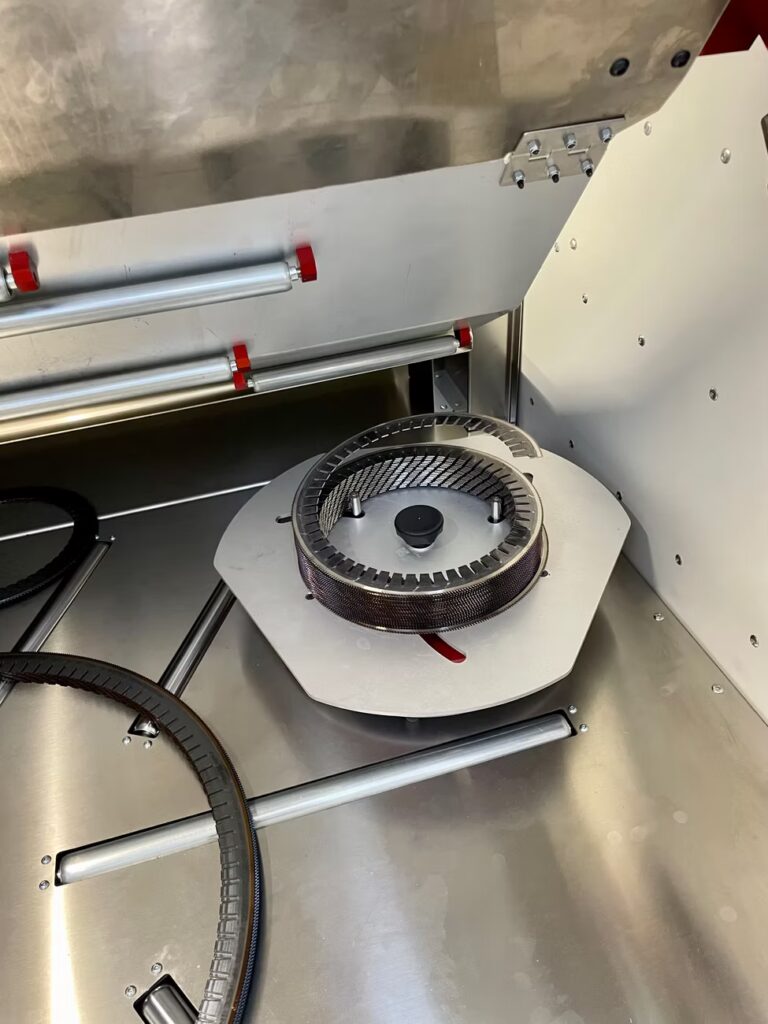

Rotary bending has always been the slow link in die production—limited by outdated systems, manual adjustments, and added equipment for specialized work. That ends with the RotaPro. Delivering a 25% speed boost over the RotaNeXt, it bends rotary rule faster, cleaner, and with unmatched precision. Its electric multi-tool cartridge powers through cutting, mitting, notching, and perforation, while optional cartridges handle laser crease, EVOL gate holes, and more. Fully automated and built to scale, RotaPro is the bender that keeps up with demand—and pushes your shop miles ahead of the curve.