Remove the Bottleneck, Boost Production

Manual rubber placement slows production, ties up skilled labor, and introduces costly inconsistencies—even in shops that have already automated cutting and bending. It’s the last obstacle standing between you and full-speed efficiency.

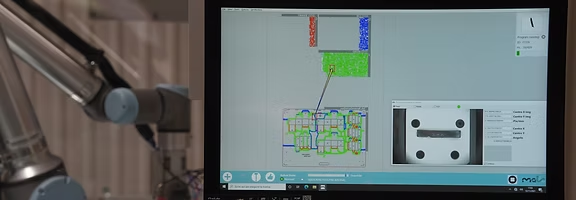

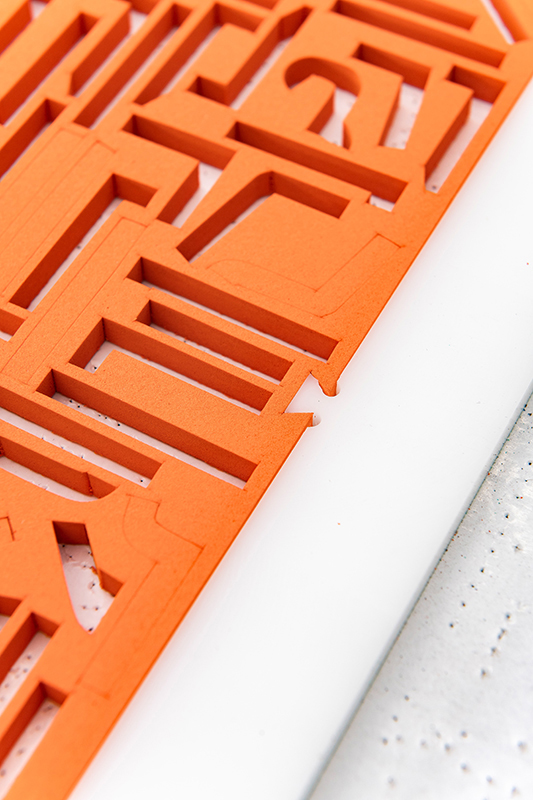

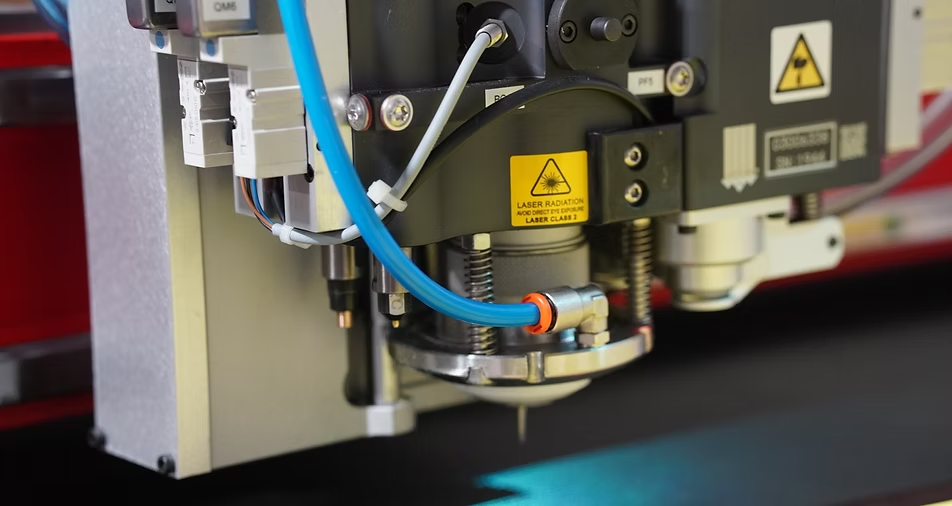

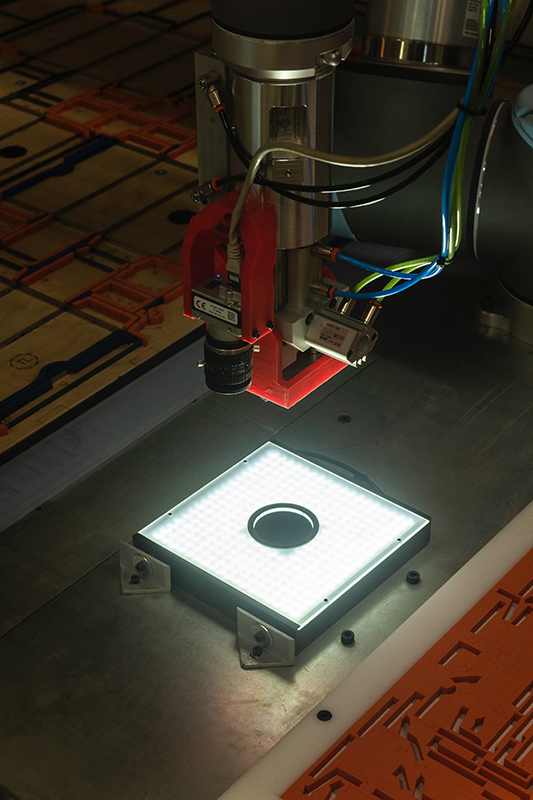

The Rubbot 2100 eliminates that barrier. As the only fully automatic rubber placement machine on the market, it installs up to three types of rubber at once, reduces waste by 30%, and integrates seamlessly with the RubbA cutting system. If you're ready to streamline operations and let your team focus on higher-value work, the Rubbot 2100 is the final piece your shop’s been missing.

The Rubbot 2100 eliminates that barrier. As the only fully automatic rubber placement machine on the market, it installs up to three types of rubber at once, reduces waste by 30%, and integrates seamlessly with the RubbA cutting system. If you're ready to streamline operations and let your team focus on higher-value work, the Rubbot 2100 is the final piece your shop’s been missing.