Outdated Routers Are Holding You Back

In today’s fast-paced industry, relying on old router tech means falling behind. Manual adjustments, inconsistent milling, and no real-time tracking lead to wasted materials, costly rework, and missed opportunities. Without automation or data insights, even the best die shops struggle to keep up with rising demands and tighter margins.

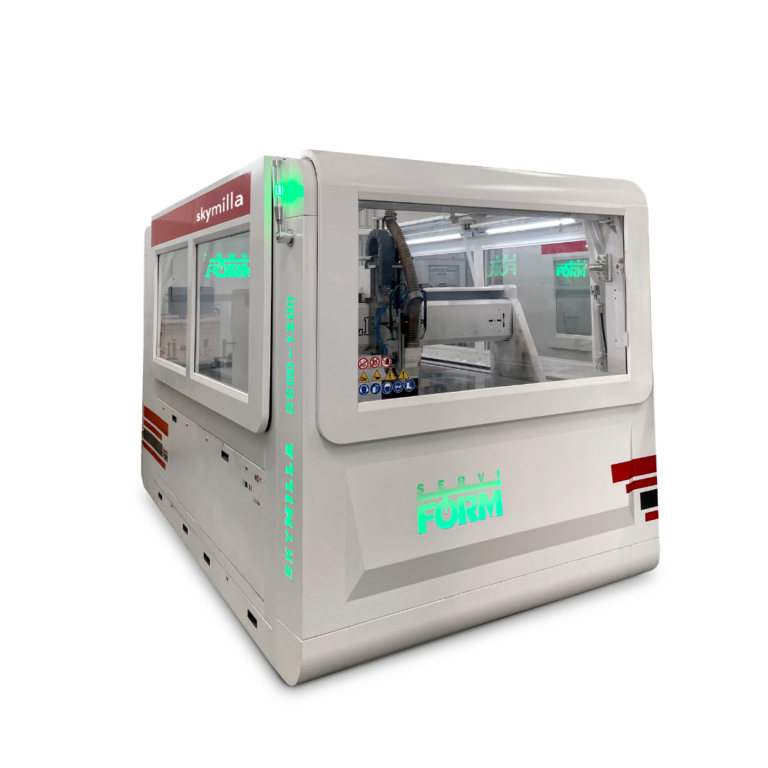

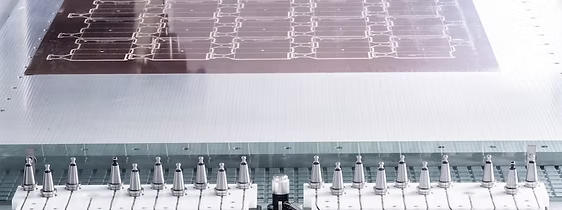

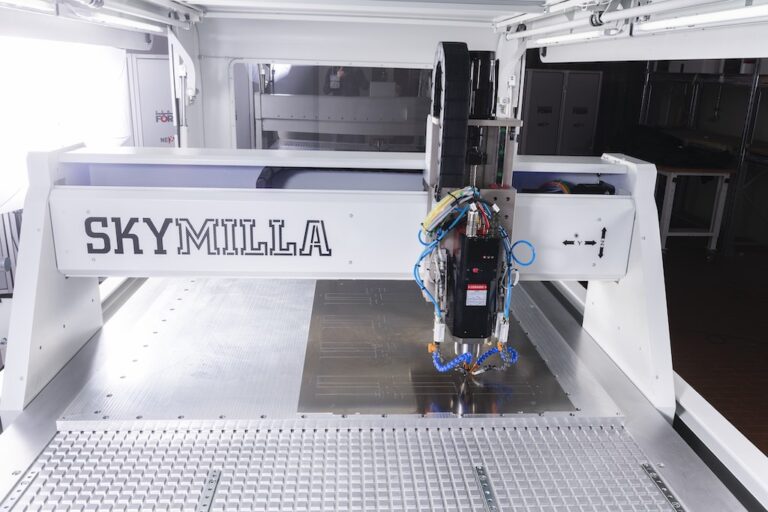

The SkyMilla is ngineered for the diedmaker ready to lead, SkyMilla brings precision, speed, and smart automation into one powerful machine. With an integrated vacuum system for rock-solid stability, seamless Windows 10 integration, and Industry 4.0-ready analytics, it’s built to cut steel and phenolic counters faster and smarter. Say goodbye to rework and hello to next-level performance.

The SkyMilla is ngineered for the diedmaker ready to lead, SkyMilla brings precision, speed, and smart automation into one powerful machine. With an integrated vacuum system for rock-solid stability, seamless Windows 10 integration, and Industry 4.0-ready analytics, it’s built to cut steel and phenolic counters faster and smarter. Say goodbye to rework and hello to next-level performance.